Tăng Minh Phát đại lý phân phối độc quyền sản phẩm chính hãng Temavasconi tại Việt Nam - Đại lý Temavasconi tại Việt Nam

Linh sản phẩm Temavasconi tại Việt Nam: http://maymoctudonghoa.com/temavasconi-vietnam/

Temavasconi là một Công ty lớn mà với thiết bị của mình có thể theo nhu cầu luôn thay đổi của thiên niên kỷ.

KHAI THÁC: Chúng tôi cam kết cung cấp sự hài lòng hoàn toàn của khách hàng, dịch vụ tuyệt vời thông qua nhân viên có trình độ cao và chất lượng sản phẩm của chúng tôi. te.ma. những nỗ lực tập trung cung cấp thiết bị xử lý có trình độ cao và dịch vụ chuyên nghiệp nhất hiện có trên thị trường thế giới.

CAM KẾT: Temavasconi tài trợ mà mỗi công cụ duy nhất được thực hiện với mức độ chuyên nghiệp cao nhất. Hành vi của khách hàng là điều tối quan trọng: hầu hết các thiết bị và công nghệ tiên tiến và sự cống hiến đầy đủ của chúng tôi là chìa khóa thành công của chúng tôi liên quan đến việc sản xuất máy đo.

ĐÁNG TIN CẬY: Do ông Angelo Vasconi thành lập năm 1954 là cơ sở của năm thập kỷ nghiên cứu cho chất lượng tuyệt vời trong mỗi sản phẩm được giao. Là công ty hàng đầu trong ngành, hàng đầu của chúng tôi đã dẫn đầu với các tính năng sản phẩm mới đột phá và lợi ích giá trị gia tăng cho khách hàng.

ĐỔI MỚI: Temavasconicó niềm tự hào là Công ty được lựa chọn bởi các nhà lãnh đạo thị trường toàn cầu. Mục đích của chúng tôi là tiếp tục phát triển các sản phẩm và cấu trúc của mình để luôn được cập nhật, đối mặt với mọi thách thức trong tương lai.

Dòng sản phẩm của hãng Temavasconi:

|

No. |

Type |

Description |

Note |

||

|

1 |

GTMP series |

ORIFICE FLANGE UNIONS FOR FLOW MEASUREMENT |

Types: slip-on flanges (SO), - fig. 1 welding neck flanges, (WN), - fig.2 ring type joint welding neck flanges (WN RJ), - fig. 3 piezometer ring etc. |

The calibrated orifice flange is the most simple and economic methode for a flow measurement of liquids or gases |

|

|

2 |

PTO series |

PADDLE TYPE ORIFICE FLANGES PLATES |

Types: |

|

|

|

3 |

DTF series |

PRECISION FLOWMETER ACCURACY 0.5% |

It can be supplied with SMART electronic transmitter, output 4-20mA, and three-way manifolds. Process connection flanged or thread. Standard material st. st. AISI316 |

||

|

4 |

PT series |

PITOT TUBES |

The magnitude factor of Pitot Venturi depend on the position of calibrating ring. When required and extra price, flow calculation can be made for determining the «dp». In this case specify: |

||

|

5 |

CVT series |

VENTURI TUBE |

Types: |

||

|

6 |

LRF series |

LONG-RADIUS FLOW NOZZLES |

Types: |

|

|

|

7 |

ICC series |

INSTRUMENTS SEAL POTS, CONDENSING CHAMBERS AND INSTRUMENT AIR |

Types: |

||

|

Gas-Filled and Bimetal Thermometers |

|||||

|

No. |

Type |

Description |

Note |

||

|

1 |

TB900 series |

Type 914 |

|

Installed on every chemical, petrochemical plants, onshore and offshore applications, |

|

|

Type 910 |

|||||

|

Type 911 |

|||||

|

2 |

TM800 series |

Type 801 |

Direct, radial lower stem |

Installed on every chemical, petrochemical plants, onshore and offshore applications and machinery, food and pharmaceutical industry |

|

|

Type 802 |

Direct, radial stem at 45° |

||||

|

Type 803 |

Direct, rear stem |

||||

|

Type 804 |

Direct, radial stem at 90° |

||||

|

Type 809 |

Direct, lower adjustable stem |

||||

|

Type 805 |

Wall, rear flange remote mounting |

||||

|

Type 806 |

Bracket for wall mounting , remote |

||||

|

Type 807 |

Panel, front flange rear central stem |

||||

|

Type 808 |

Wall, rear flange rear central stem |

||||

|

Type 810 |

Panel, “U” clamp, rear eccentric stem |

||||

|

3 |

TM700 series |

Type 701/S |

|

Be suitable to be installed on engine, machines, or plants in presence of strong vibrations |

|

|

Type 701/M |

|||||

|

4 |

TM400 series |

Type 401 |

Dimensions 144x144 |

Be specific for panel mounting with standard case dimensions suitable for mounting in parallel with electric indicators |

|

|

Type 401 |

Dimensions 96x96 |

||||

|

Type 402 |

Dimensions 96x96 |

||||

|

Type 403 |

Dimensions 144x72 |

||||

|

5 |

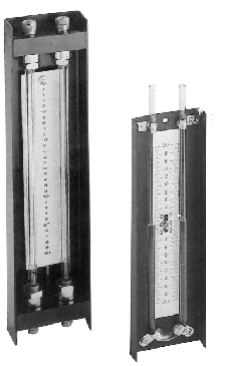

TV1000 series |

Type 1002/ V |

250x55 |

Be particularly indicated for those industrial applications (petrochemical, air conditioning, food industry, chemical, etc. ) where there are difficulties of location |

|

|

Type 1001/ V |

180x55 |

||||

|

6 |

TV1006 series |

Type 1006/A |

|

Be manufactured with ranges and relatives divisions of graduation according to the nominal dimensions |

|

|

Type 1006/B |

|||||

|

Type 1006/C |

|||||

|

Type 1006/D |

|||||

|

Type 1006/E |

|||||

|

Type 1006/F |

|||||

|

Type 1006/G |

|||||

|

7 |

TV1009 series |

TECHNICAL CHARACTERISTICS |

Be particularly indicated for use in laboratory or where is required high reading accuracy . |

||

|

8 |

Type TS8-1 |

BASE THERMO-SENSOR INSERT for RTD or Thermocouple |

APPLICATIONS |

||

|

9 |

Type TS8-2 |

CERAMIC THERMO-SENSOR INSERT con Thermocouple E/J/K/N |

APPLICATIONS |

||

|

10 |

Type TS8-3 |

CERAMIC THERMOMETRIC INSERT with thermocouple S/R/B |

APPLICATIONS |

||

|

11 |

TYPE CT8-21 |

THERMOMETRIC COMPLEX with thermowell, at high response speed |

APPLICATIONS |

||

|

12 |

TYPE CT8-22 |

THERMOMETRIC COMPLEX with stepped end, high response speed |

APPLICATIONS |

||

|

13 |

TYPE TS8-40 |

THERMOCOUPLE FOR HIGH TEMPERATURE |

APPLICATIONS |

||

|

14 |

TYPE TS8-41 |

THERMOCOUPLE FOR HIGH TEMPERATURE with ceramic thermowell |

APPLICATIONS |

||

|

15 |

TYPE CT8-70 |

THERMOMETRIC COMPLEX FOR SKIN MEASUREMENT |

APPLICATIONS |

||

|

16 |

TYPE CTB |

THERMOMETRIC COMPLEX with barstock thermowell acc. to UNI/DIN and ISA |

APPLICATIONS |

||

|

17 |

TYPE CTL |

THERMOMETRIC COMPLEX WITHOUT THERMOWELL |

APPLICATIONS |

||

|

18 |

TYPE CTT |

THERMOMETRIC COMPLEX with thermowell from pipe, |

APPLICATIONS |

||

|

19 |

TYPE CT8-81 |

THERMOMETRIC COMPLEX FAST RESPONSE “RTD” |

APPLICATIONS |

||

|

20 |

TYPE TS8-81 |

FAST RESPONSE THERMOMETRIC COMPLEX “TC” WITH CONNECTOR |

APPLICATIONS |

||

|

No. |

Type |

Model |

Description |

|

1 |

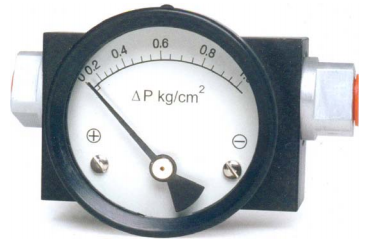

DPMS8 series |

Weatherproof Differential Pressure Switches |

|

|

2 |

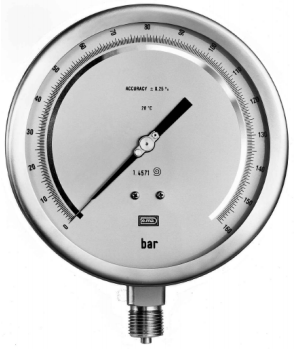

PBS8 series |

Bourdon Tube Type Weatherproof Pressure Switches |

|

|

3 |

PCS8 series |

Capsule Type Weatherproof Pressure Switches |

|

|

4 |

PMS8.1 series |

Diaphragm Type Weatherproof Pressure Switches |

|

|

5 |

PMS8.2 series |

Weatherproof Low Range Pressure Switches |

|

|

6 |

TMS8 series |

Gas Exphansion Type Weatherproof Temperature Switches |

|

|

Electric Contacts for Pressure and Temperature gauges, Trasmitters and electronic instrumentation |

|||

|

No. |

Type |

Model |

Description |

|

1 |

Electric Alarm Contacts |

Types Of Contacts |

|

|

Low Action Contacts |

Nominal operating voltage: 250 V max. |

||

|

Inductive Contacts |

Rated voltage: 8 V = (Ri ~ 1KOhm). |

||

|

Snap-Action Contacts (With Screwed-In Magnets) |

Nominal operating voltage: 250V max. |

||

|

Electronic Contacts |

|

||

|

2 |

Indicating - Dial, Pressure And Temprature Switch |

STANDARD SPECIFICATIONS |

|

|

3 |

MB800 series |

|

|

Đại lý Temavasconi tại Việt Nam - Đại lý phân phối độc quyền Temavasconi Việt Nam

- Mark-10 VietNam

- AT2E VietNam

- Teclock VietNam

- WISE Control VietNam

- Nireco VietNam

- Econex VietNam

- Redlion VietNam

- Matsushima VietNam

- Bircher VietNam

- Masibus VietNam

- KELLER VietNam

- Atlas Copco VietNam

- Schneider Electric Viet Nam

- Masoneilan VietNam

- Aira VietNam

- ROTORK VietNam

- Pavone Sistemi VietNam

- Fox Instruments VietNam

- TEMPSENS VietNam

- RADIX VietNam

- TDK Lambda VietNam

- AMETEK VietNam

- LAND AMETEK VietNam

- PISCO VietNam

- TOKYO KEIKI VietNam

- Pce-Instruments VietNam

- Elettrotekkabel VietNam

- Pora VietNam

- Bronkhorst VietNam

- Fairchild VietNam

- Mehrer VietNam

- Baummuller VietNam

- SPOHN BURKHARDT VietNam

- Daiichi Electric VietNam

- Beckhoff VietNam

- DMN-WESTINGHOUSE VietNam

- Ohkura VietNam

- Temavasconi VietNam

- CEIA VietNam

- Hans-Schmidt VietNam

- Okazaki-MFG VietNam

- IBA-AG VietNam

- Adlerspa VietNam

- Prosensor VietNam

- IPF-Electronic VietNam

- Elco Holding VietNam

- Autrol VietNam

- Mdexx VietNam

- Staubli VietNam

- Krebs and Riede VietNam

- WATANABE VietNam

- Koganei Vietnam

- Norgren VietNam

- Festo VietNam

- Schenck Process VietNam

- Bussmann VietNam

- Minimax VietNam

- Cometsystem VietNam

- Knick-International Viet Nam

- Meggitt VietNam

- Riels VietNam

- Tek-trol VietNam

- Gastron VietNam

- Sauter controls VietNam

- Lapar Viet Nam

- Krohne VietNam

- BCS Italy VietNam

- Vega VietNam

- Bekomat VietNam

- Sitec-Components VietNam

- CS Instrument Viet Nam

- Gemu VietNam

- SEMIKRON Viet Nam

- Spare Parts

- Labom Viet Nam

- Hirose Valves VietNam

- Medenus VietNam

- Fotoelektrik Pauly VietNam

- Helukabel VietNam

- Ashcroft VietNam

- Rechner sensor VietNam

- Fireye VietNam

- Brooks Instrument VietNam

- Kometer VietNam

- Tester Sangyo VietNam

- Brugger Feinmechanik VietNam

- Kracht Corp VietNam

- Thwing Albert VietNam

- Guenther VietNam

- ThermoTech Sensors VietNam

- Dwyer VietNam

-

Trực tuyến:4

-

Hôm nay:795

-

Tuần này:795

-

Tháng trước:10648

-

Tất cả:1978058

Email:

Email: